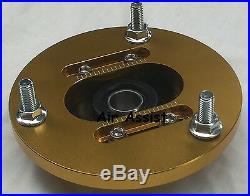

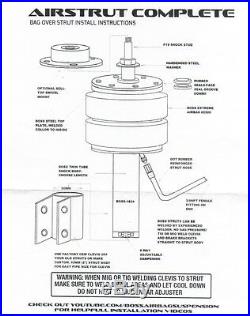

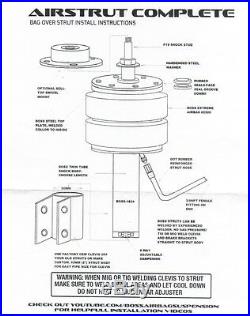

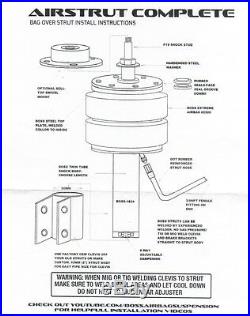

This is a brand new pair of BOSS air bag over strut suspension kit to suit front of Commodore. All model commodores except VE. From way back in VR days to current. This is for 2 x struts so you can do both sides. These are a direct replacement of your old struts. There are no modifications required to the car and they can be readily removed and conventional struts can go straight back in, for what ever reason. The strut is 12 way adjustable so you can choose a soft rebound (bounce) or a firm sporty ride (no bounce). The bag can be run at what ever pressure you desire. Soft (say 15-20 psi) will be like riding on a pillow and it will be low to the ground. You can add more air and have a more firm ride and it will be higher off the ground. There’s no limit to what the bags can take as they can withstand hundreds of psi and many tonnes of weight. We run these bags in commercial vehicles too remember. If you get one of our in cab kits as well you can pump them up from inside the car. If you like the low look but cant get up driveways then pump them up when needed and you can get heights even taller than standard suspension. These come with out patented bell tops for mounting the top of the strut to your car. These are adjustable and have a swivel bearing to accommodate tilt and varying lean. Has heavy duty air lines (hydraulic line) for near the wheel where conditions are harsh. But also have poly line with push connect fittings and valves so you can manually inflate the bags with a tyre valve for each. That way you could get these in and operational before you get around to running a compressor and tank for in car control at a later stage. We can help with all that gear too. The bags are our ever popular and common 2500 series bag. It is tried and tested in over 20,000 vehicles and they date back 15+ years and still going. So rest assured the bags are proven to be the best and can be readily replaced if needed. What you do need to do is cut the old mount off the bottom of your old strut and weld it to the bottom of these struts. The struts are mild steel untreated and unpained for ease of welding. A home welder is good enough. Also might pay to transfer the brake line bracket to the new strut in the same fashion. But that’s all there is by way of fabricating. Note you can slide the bottom mount up and down the new strut to a position you like before welding and that can accommodate the super low needs or a taller ride. How low does it go? You can sit the car on the ground if you want. Before you get that low you will find the car will sit on the tyres first. How high does it go? You can lift the front. Of the car to 2.0 taller than standard. Perfect for clearing steep driveways. Can they carry heavy loads? You can run at what ever height you want with even the heaviest loads. Mind you the front doesnt have much of a variable load. Anyway, the bags are up for it. You can carry whatever load you want at what ever height you want. Just add more air to get more height. Can I drift or drag with these? – yes we get asked that and yes you can. And when its time to drive home, clear speed humps or get it up onto a trailer just pump the bags up. Oh and yes it is like driving on pillow soft air. For a very soft ride just run low pressures. For a stiff firm ride just ride with higher pressures. Depends if you have IRS, leaf or live axle coil. We do them all except VE rear struts at this stage. The kit is complete. Bell Top brackets for top. 12 Way adustable Struts. Air Bags with fastening bolts and washers. Air Lines – Heavy Duty for wheel area plus poly line to valves. Air Fittings and valves for air lines. Easy to follow instructions with pics. Are the bags strong – absolutely. The thickness and toughness of these bags is somewhat heavier than the sidewalls of your tyres. Your tyres are running along the ground a lot more exposed to sticks and rocks than your air bags, and the bags are heavier. We just dont get bags sustaining damage. You can put that fear to rest. We can also do tanks for tyres or digital displays. Lets quickly kick a few goals.. Normal operating pressures are just like your tyres – 25 psi to 50 psi for normal descent loads. The rubber in our BOSS bags is heavier than the rubber in your tyres. They never get damaged by stones or sticks. You can carry what ever load you want at what ever height you want, even if the car is normally lowered. Individual components like a bag are all replaceable. We are Australian and now have over 25,000 customers all over Aus. We do virtually every Ute, 4WD or Van and pride ourselves in not copying others. We speak with roo shooters, caravaners, tradies, farmers and alike all over Aus all day everyday. We also look after workshops and resellers. We are here to help. The steel brackets are laser cut, mig welded and powder coated black with the appropriate preparations for best adhesion and anti corrosion. We are phasing out the electroplating. Powder coating looks better, lasts longer and the process is better for the environment. The kit exceeds Australian Design Rule (ADR) standards. Any old air compressor will pump these up. Could be at a servo, a workshop compressor or a 12V cig lighter compressor. But it’s really cool to mount a compressor and air tank on board so you can adjust your air bags with the flick of a switch. See below for in cab options. Note the in cab kits below are traditionally for 2 x bags but for a little extra we can work out a great price to do all 4 bags if you get bags for the front as well. We have 3 In Car Kits to choose from… PX01 In Cab is our newest and now most popular. PX02 is same as PX01 but with our larger PX02 compressor.. Our PX07 In Cab Kit is the most comprehensive with our big PX07 compressor and tank also great for pumping tyres, running air horns and tools.. With this upgrade we take out the twin needle gauge and the 2 manual dump valves and replace them with the following.. 1 x LED Digitial Gauge – twin read out. 1 x Mounting plate. 2 x air down electric solenoids with 1/4 T-piece. 2 x push button switches to activate the solenoids. 2 x sender units with 1/4 T-piece. All of our gear may be picked up from our official BOSS development center in Labrador on the Gold Coast or we can send anywhere in Aus (or with express options) or Worldwide at affordable rates. Almost every air bag application we do is bolt in. No welding or cutting or drilling. We make that a mandatory requirement when we develop a new kit. And we will make sure we do better. We wont be beaten on price, quality or service. Happy customers is our key to success. People often ask why or how are we so much cheaper than Firestone. So our costs are way down and if we charged Firestone prices we would be ripping you off. Our bags are not permanently attached to the mounting brackets. That means you can replace a bag if you have to without the costly new brackets as well. No need for qualified installers, anyone can fit our gear, its easy and there’s no crazy ideas of how long 5 years is. The way we see it, if you are happy you will tell your friends and our next customer could be one of your mates. So even in 15 years we are still going to look after you. It’s how we roll. I sell brackets and bags individually to people who change cars or need spares. Consider this – there are over 15,000 BOSS kits out there in Australia alone. That’s 30,000 air bags. I sell replacement bags at a rate of about 4 bags per month. That tells us the bags are lasting a very long time and just not wearing out. Of course they can and they save heaps. Sometimes they just need new top brackets. We talk with farmers, tradies and travelers every day about their load carrying and air system needs and we take pride in making our mark on Australia. We have been doing air suspension for over 15 years and have over 20,000 Aussie customers out there running BOSS air suspension products. Over the years we make improvements where we can and so by now we have become a market leader recognised for having the best product at the best prices. BOSS also have a development center in Canada looking after our Canadian and American interests. We have a lot of exciting vehicle applications in the USA that eventually filter through to Australia and other parts of the world and so we have a very extensive range which includes all the American pick ups as well as the old classic cars like Chev and Buick. At BOSS we dont copy others – To begin with we dont trust the others to get it right. But more importantly the others dont have anything to copy. BOSS are the first to get hold of new vehicle models and get kits to market having tried and tested them, fully getting to understand the vehicle and the engineering required. As such BOSS have the widest range of applications for Australian and USA markets and we are onto all the new models even before they are released. Also other brands seem content with drilling chassis rails. Sure it means less kits fit more vehicles but no one wants to compromise their vehicle so we put in that extra bit of attention and the results are in the bag. BOSS have the most comprehensively wide range of accessories as well. All of our air compressors can be rebuilt and we stock those parts. We have tanks, pressure switches, water filters, braided lines, digital pressure gauges, everything for in car operation of your bags, the list goes on and on. BOSS air bags are manufactured in our BOSS factory with our own machines to our own exacting standards and specifications. We strongly believe it’s the only way of maintaining strict control over the bags. Here are some interesting facts… It takes over 20 minutes for each bag to go from the raw un-cured blended rubber to a cured air bag. 1 machine can only make 1 bag at a time. Its not just the thickness of the rubber that gives the bag its strength but also the angle of the reinforcing cords and design of the woven beads. The proprietary ballistic material used for the woven reinforcing on the airbag wall, along with the specific spacing and angle of the weave, is what gives our air bag its unique strength. The bead ring ends of the bag are constructed of 4 Hi-tensile cords at each end, ensuring that the top and bottom hold their shape and cant be pulled away from the Aluminium clamping ring. The center of the air bag (the part of the bag with the most stress) is constructed using 9 strands of Hi-Tensile steel to form an indestructible center support. Our competitors’s bags have less than half these strands. The BOSS airbag machines are operated at over 400psi while the curing process is taking place with very high heat. There’s an internal bladder pushing the airbag case into the mould ensuring consistency throughout the airbag wall. Each air bag machine has over 50 tons of clamping pressure on the mold during curing. Effectively these are desperately over engineered as there’s no way you could ever exert over 50t and 400 psi on a bag in your vehicle. The factory tests selected bags to destruction within a controlled chamber to ensure continued bag quality and identify possible ways to constantly improve the design and technique. We have just recently released the exciting new EX-2 Bags. They have a 5 year leak free guarantee. Tooling was modified to provide for a heavier and wider rim width. BEWARE: Some other brands use crimped-on end caps. Crimped or Banded air bags are prone to popping the end caps out at anything over 100psi and often simply pull the end caps out when the bag is fully extended. BOSS air bags are undeniably the strongest in the automotive industry and exceed any other air bag brands by nearly double. Ver 100 different air bag leaf and coil load assist kits. BOSS does coil replacements kits. BOSS does air struts. BOSS does full air suspension systems. BOSS does package deals with different in cab and compressor options. BOSS does Coil O. Ver struts with coils. BOSS does Shock Absorbers. And of course, BOSS does air suspension for Harley Davidson bikes… So you see BOSS is 100% focussed and committed to delivering all the best gear. Here is a selection of our other popular accessories and add ons. Like we said, no one else offers such a huge list of optional bits. Ride like a BOSS. The item “BOSS FRONT Air Bag Suspension kit Holden Commodore HSV Club Sport SS R8″ is in sale since Sunday, December 25, 2016. This item is in the category “Vehicle Parts & Accessories\Car & Truck Parts\Suspension, Steering\Other”. The seller is “air_assist_suspension” and is located in Labrador, QLD. This item can be shipped worldwide.

- Brand: BOSS

- Manufacturer Part Number: BOSS Bag Over Strut Commodore